Discover how manufacturers can use OSINT to conduct real-time monitoring, supplier assessment, geopolitical risk analysis and other crucial functions that together create a comprehensive intelligence framework for modern manufacturing operations.

In today's interconnected manufacturing landscape, supply chain visibility has become a critical competitive advantage. Open-source Intelligence (OSINT) provides manufacturers with powerful capabilities to monitor, assess and predict supply chain dynamics without requiring expensive proprietary systems. By leveraging publicly available information across the surface web, social media and even darknet channels, manufacturing companies can identify risks, opportunities and disruptions before they impact their operations.

How does OSINT enhance manufacturing supply chain visibility?

OSINT can help improve supply chains of the manufacturing sector in numerous ways by leveraging publicly available information to monitor, analyze and optimize operations. Here are the main areas in which OSINT can enhance these processes:

Real-time disruption monitoring

OSINT can be used to track events, news, weather reports and social media to detect early warning signs about natural disasters, strikes or logistical delays (e.g., port closures or changes to global supply routes).

For example, during the Al Houthi attacks in the Red Sea, monitoring news outlets informed companies early about attacks occurring in real time that affected marine routes, consequently delaying supply materials for manufacturing companies. This advanced intelligence allowed proactive supply chain managers to reroute shipments and prioritize alternative sourcing before widespread disruptions impacted production schedules.

Here are some websites for monitoring news and weather worldwide:

- Al Jazeera News - For Middle East news

- BBC - World news

- CNN - USA and world news

- China Law Translate (CLT) - English-language source for news and analysis on Chinese law

- China Daily - China news

- POLITICO - EU news source

- AccuWeather - Weather forecasts

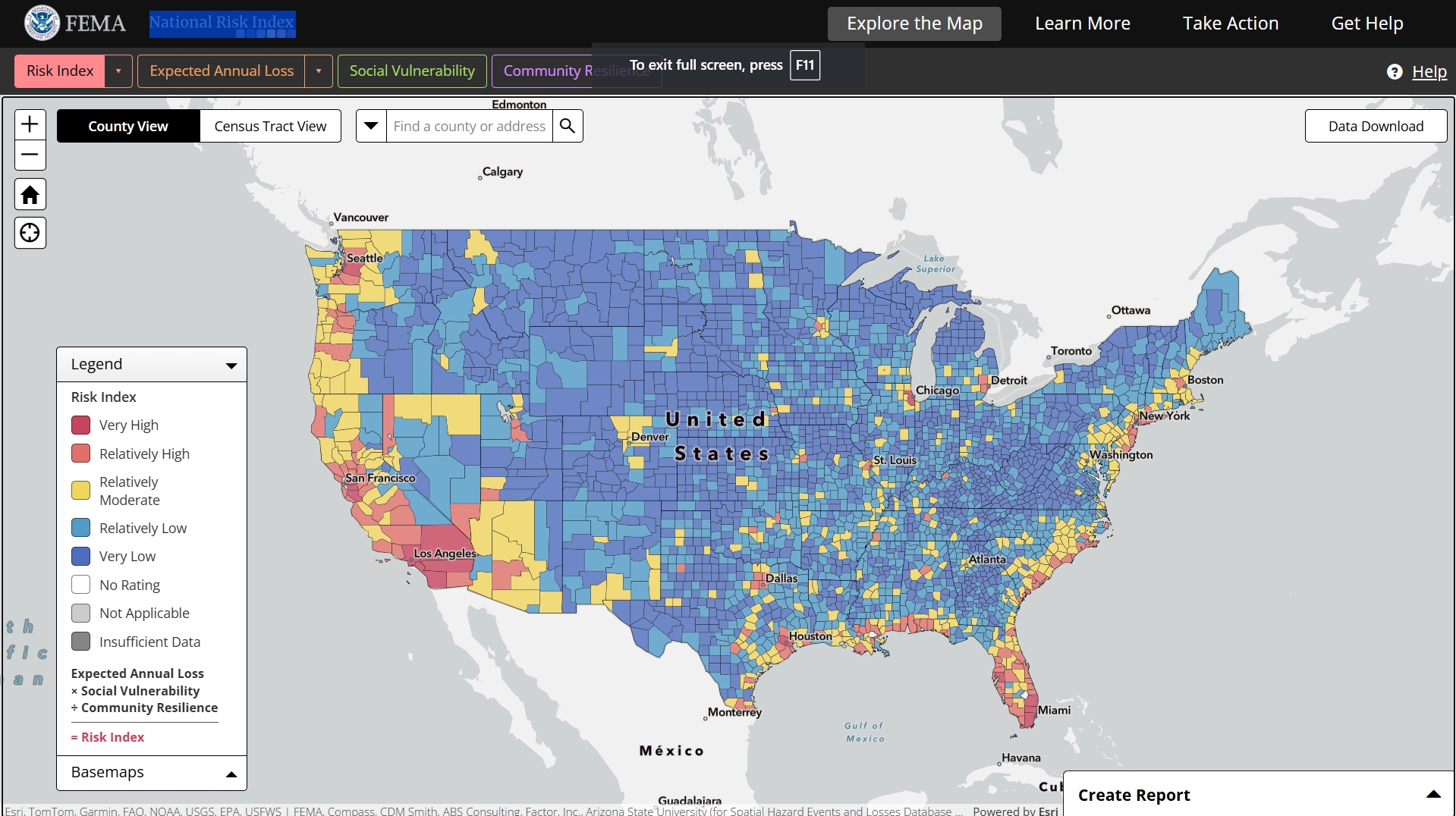

- National Risk Index - Natural disasters risk index across the USA (see Figure 1)

Figure 1 - U.S.A. national risk map

Real-time supplier monitoring and assessment

Manufacturing companies are not working in isolation; they need to continuously import/export materials from different countries to remain operational. This necessitates forming relationships with various suppliers worldwide. OSINT can help collect information about those suppliers to ensure supply chain networks are not affected if any of these suppliers encounter a problem or are operating in risky environments, which include both war zones and countries with unstable political governments.

Darknet networks, such as the TOR and I2P networks, should be monitored for any leaked information about any supplier to act promptly if this will impact manufacturing operations.

We can collect information about suppliers using social media, the darknet and the surface web using the following resources:

- Corporate registry databases reveal ownership structures and financial status of suppliers. Here are some registry databases:

- Trade journals showcase supplier capacity expansions or contractions. Here are links to some popular trade journals.

- Satellite imagery detects physical plant disruptions or irregularities. Google Map pro and EOS Data Analytics

- Court filings exposing potential legal troubles or sanctions violations. Check USA Sanctions List Search and EU Sanctions Map

- Employment trends reveal workforce challenges

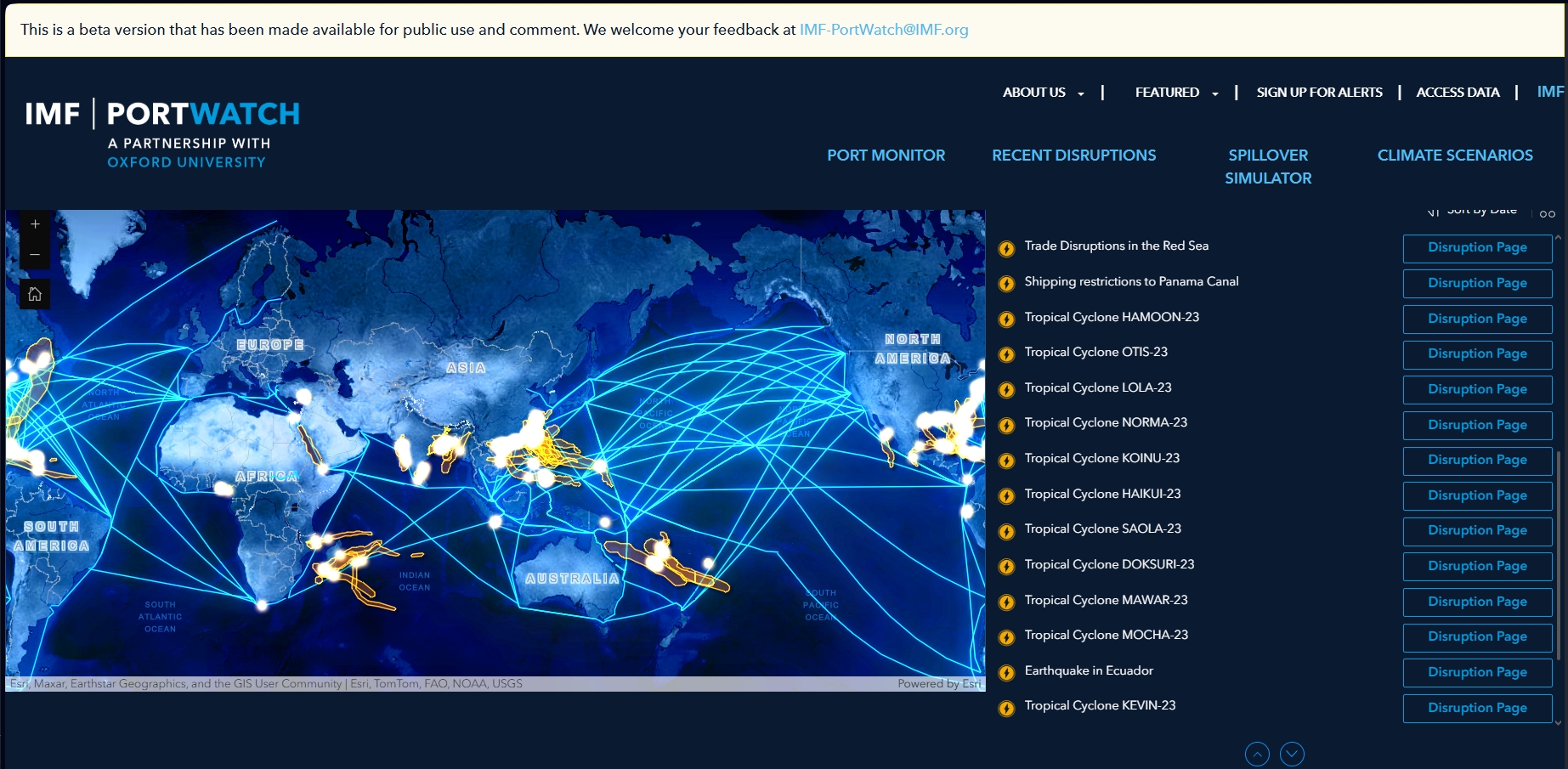

- Port authority records indicate shipping disruptions. Check PortWatch for monitoring areas affected by current and recent trade disruptions (see Figure 2).

Figure 2 - PorWatch monitors disruptions to trade on a global level

- Local news sources in supplier regions revealing issues before they hit global headlines. Some local news sources include Google News for USA, Channel NewsAsia (CNA) for Singapore ,Shaanxi for China and Asia Times for different Asian countries.

Geopolitical risk assessment

Geopolitical risks—such as trade wars, sanctions, conflicts and policy shifts—can disrupt supply chains overnight. By analyzing publicly available data, OSINT can help manufacturers anticipate, monitor and mitigate these risks.

Here are some sources to begin researching geopolitical risk assessment and its impact on supply chains:

- World Economic Forum - Global Risks Report 2025

- Marsh - Political Risk Report 2025

- KPMG - Top Geopolitical Risks 2025

- U.S. Department of Commerce - International Trade Administration (ITA)

Logistics and transportation tracking

Logistics and transportation tracking play a vital role in assessing the movement of goods, materials and people, whether for strategic, economic or security purposes. By leveraging publicly available data, OSINT analysts can gain near real-time visibility into global and regional supply chains. Key OSINT sources and methods that help in this field include:

- Vessel Tracking using sources such as MarineTraffic or VesselFinder

- Port congestion information through ports authorities' reports and third-party services such as: Gocomet and SeaVantage

- Infrastructure disruption reports. For instance, road closures, railway outages, port shutdowns or cyberattacks on logistics systems can all impact transportation. Here are some resources to get information about infrastructure disruption:

- Bureau of Transportation Statistics (BTS) - U.S. Department of Transportation

- Network Rail - Service disruptions (UK)

Market intelligence

OSINT plays a critical role in generating actionable insights on raw materials, components and sourcing strategies. This is particularly valuable for procurement teams, supply chain risk analysts and strategic planners aiming to stay ahead of market shifts and disruptions. Through OSINT monitoring, organizations can track:

- Price fluctuations detection: Through commodities exchanges (e.g., London Metal Exchange, NASDAQ), trade publications and market analytics platforms (e.g., Trading Economics, Index Mundi). For example, by tracking lithium carbonate price movements across Asian markets, we can detect early signals of battery cost increases before supplier notifications.

- Availability forecasts: This includes public production data, export/import statistics and analyst forecasts, offering visibility into the future availability of key resources. Here are some sources for such forecasts:

- Emerging alternatives: Scientific publications, patent databases (e.g., Google Patents, WIPO, Espacenet) and innovation tracking platforms (like CB Insights, Crunchbase or arXiv) are used to identify novel materials and synthetic substitutes

- Competitive intelligence: Monitoring job postings, factory permits and logistics tenders helps reveal competitor capacity investments and sourcing shifts. Here are some sources to inspect these competitors' areas:

- Job posting websites: Indeed, LinkedIn, Glassdoor, CareerBuilder and SimplyHired

- Factory permits and business license: Building Permits Survey (BPS), UK Public Registers Online and EU Registration, permits and licenses

Monitor for counterfeit components

OSINT enables proactive detection and tracking of counterfeit or unauthorized components through a mix of sources, such as:

- Online marketplaces: Global trading portals can reveal suspicious and counterfeit products. For instance, low-priced products belonging to high-profile companies are a red alert. Here are some online marketplaces to start your search: Alibaba, AliExpress, DHgate and Made-in-China

- Customs seizure: Governments worldwide publish reports when seizing fabricated products and their trafficking routes. Here are some sources:

- U.S. Customs and Border Protection (CBP)

- EUROPOL / EUIPO | Counterfeiting and Product Piracy

- World Customs Organization (WCO) | Annual illicit trade reports

- Forums, Reddit and Tech community reports: People commonly share firsthand encounters with counterfeit parts in public forums or subreddit threads. Here are some sources to search these locations:

- StackExchange (Electronics), Reddit (e.g., r/electronics, r/hardware, r/software)

- Technical communities discussing faulty or fake components such as: EEVblog Forum, Element14 Community and CircuitLab Discussion Forum

- Vendor blacklists and whitelists: Many vendors maintain a list of bad and good suppliers. Here are some sources:

- GIDEP (Government-Industry Data Exchange Program)

- ERAI: Counterfeit Electronics Database

- TrustedParts.com | Search authorized component distributors

- Visual analysis: Reverse image search and other visual analysis tools can be used to identify fake components by analyzing logos, part markings or datasheets (Electronic Parts Datasheet Search, Datasheet Archive). Here are some reverse image search engines:

Predictive analytics for demand

Different OSINT sources can be used to predict shifts in demand or supplies. For instance, by using OSINT sources we can integrate economic indicators (e.g., Global Supply Chain Pressure Index), weather forecasts and social sentiment to predict future demand on a global scale. Here are some sources to facilitate this task:

- Economic indicators sources: Using data from the Global supply chain pressure index (GSCPI)

Weather forecasts: Help predict possible disruption in delivering Raw Material or Transit because of weather. Here are some weather forecast services: NOAA, Windy and MeteoGroup - Social sentiment: Scan public posts on social media platforms (X , Reddit, Facebook) to predict public sentiment about a specific product or brand. Here are some tools for sentiment analysis and to monitor trending keywords across social media:

- Brandwatch

- Google Trends

- Sentiment140 - An X sentiment analysis tool

- TextBlob - A Python library for processing textual data

- VADER-Sentiment-Analysis

OSINT transforms manufacturing supply chains by offering comprehensive visibility across multiple dimensions - from supplier monitoring and geopolitical risk assessments to counterfeit detection and predictive analytics. By systematically leveraging publicly available intelligence sources, manufacturers can anticipate disruptions, spot opportunities and maintain operational resilience in an increasingly complex global environment.

Gather intelligence quickly and securely

Silo is a digital investigations platform purpose-built to support, streamline and secure the most sensitive research. Many analysts from Fortune 500s rely on managed attribution to control your digital fingerprint and appear in-region to foreign websites. To learn more about how to protect your investigation and fast track collection, read more about Silo or start a free trial.